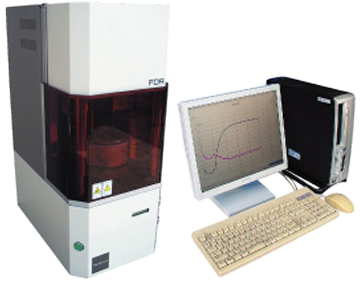

FDR Flat Die Rheometer

Model : VR-3110 Series

- Rubber and Plastics

- PROCESSING PROPERTIES

- Vulcanization Characteristics

FDR (Flat Die Rheometer) measures the torque that changes with vulcanization when a compound rubber is placed between the upper and lower flat dies at a specified temperature and a sine wave torsional vibration is applied. It is a testing machine that obtains vulcanization characteristics from max. and min. torque, changes in scorch time, vulcanization time, viscoelasticity, etc. By adopting a cone drive to get accurate sinusoidal vibration and 4-Heater Drive, excellent accuracy and reproducibility of test results have been achieved.

Furthermore, it is a state-of-the-art rheometer that has been put together in a compact shape that can be installed anywhere by thoroughly laying out each part.

As optional, we have prepared a sponging pressure measurement specification that can analyze the sponging pressure of foam rubber together with the vulcanization reaction. Program temperature control function is also available as an option.

-

Reference Standard:JIS K6300-2/ISO6502

-

Overload control: 22Nm or more

-

Test Temperature:50~230℃

-

Dimension:333(W)×520(D)×780(H)mm

Inquiries about FDR Flat Die Rheometer

TEL.+81-42-572-1397

(Monday to Friday, 9:00 am to 5:00 pm Japan Time)

FAX.+81-42-573-1520